Navigating the world of woodworking machinery can sometimes feel like walking through a dense forest; it’s easy to lose your way among the vast options available.

You’ve got to weigh your project’s specific needs against your budget, ensuring you don’t overstep financial boundaries while still grabbing a machine that won’t fall short.

Space in your workshop is another critical consideration, along with deciding between the charm of manual tools and the efficiency of electric ones.

But how do you strike the perfect balance among these factors? Join the conversation to uncover insights that could guide your next purchase.

Contents

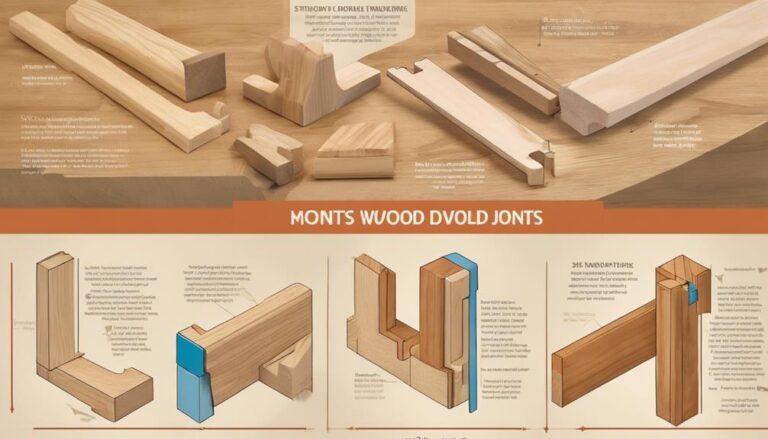

Specific Project Needs

To ensure your woodworking project’s success, it’s essential to choose machinery that precisely meets its specific requirements. Diving into the project details is your first step; understanding the scope, complexity, and unique aspects of your work will guide you in selecting the right tools.

Consulting with woodworking professionals can offer invaluable insights, aligning the machinery with your project goals. This approach not only enhances efficiency but also ensures the quality results you’re aiming for.

New Vs. Used Machinery

Having established the importance of selecting machinery that meets your project’s specific needs, it’s crucial to weigh the advantages and disadvantages of opting for new versus used woodworking machinery.

- New woodworking machinery ensures you’re at the forefront of technology and features, enhancing your workshop’s capabilities.

- Used, especially reconditioned, machinery presents a cost-effective route, making high-quality tools more accessible.

- Instruction manuals and specifications for older models are often readily available online, ensuring you can maximize your tool’s potential.

- Older models available second-hand offer the charm of affordability without necessarily sacrificing performance.

Whether you lean towards the latest models for their cutting-edge technology or prefer the more affordable options that used and reconditioned woodworking machinery offers, your choice should align with both your budget and project requirements.

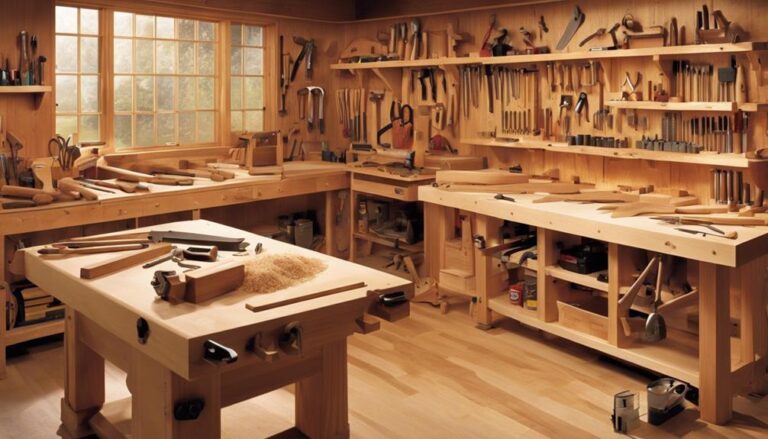

Space Considerations

Why not start by accurately measuring your workshop space to ensure the woodworking machinery you’re considering will fit without causing space constraints? Before making any purchase, taking precise dimensions of your workshop is crucial. This step guarantees the machinery will nestle into your space without hindering movement or efficiency.

If you’re working with limited room, opting for small and compact machines can dramatically improve your workshop layout. These choices not only maximize your efficiency but also contribute to maintaining an organized working environment.

Ensuring a comfortable fit for your woodworking machinery within the available space allows for smoother operation and enhances overall workflow. Remember, a well-planned workshop space is integral to creating a functional and efficient woodworking hub.

Maintenance and Operation

Ensuring your woodworking machinery undergoes regular maintenance is key to preserving its longevity and boosting efficiency. Understanding operation procedures isn’t just about pushing buttons; it’s about ensuring each piece of machinery performs at its peak. Here’s what you need to remember:

- Regular cleaning and upkeep prevent the build-up of sawdust and debris, which can impair functionality.

- Familiarizing yourself with the operation practices of each machine enhances efficiency and safety.

- Specialists can offer invaluable advice on both maintenance and operation, tailoring guidance to your machinery’s specifics.

- Efficient operation practices and preventive maintenance can significantly reduce the likelihood of costly repairs and downtime.

Budget Planning

Before diving into the selection of woodworking machinery, it’s crucial to establish a well-planned budget to guide your purchasing decisions. Researching machinery prices online provides a foundation for your budget planning. Considering second-hand options can offer more cost-effective solutions without sacrificing quality.

| Factor | Importance |

|---|---|

| Machinery Prices | Research online |

| Second-hand Options | Cost-effective |

| Features vs. Cost | Balance |

| Cost-effective Solutions | Ensure Efficiency |

| Efficient Selection | Priority |

Balancing features with cost is essential; you don’t want to overspend on unnecessary features. Opting for cost-effective solutions, such as second-hand machinery, can significantly enhance your selection process, ensuring you choose the most efficient and suitable woodworking machinery within your budget. Remember, a well-planned budget is your best tool for an efficient selection.

Conclusion

In summary, when selecting woodworking machinery, it’s vital to closely align your choices with your specific project needs.

Whether you opt for new or used equipment, remember to carefully consider your workshop space, maintenance requirements, and operational ease.

Moreover, effective budget planning can’t be overlooked; it ensures you get the best value without compromising on functionality.

By balancing these factors, you’ll equip your workspace with tools that not only meet but exceed your woodworking aspirations.