Is it truly said that the right tools make the craftsman, especially when it comes to creating custom furniture? You’ve likely heard that precision and quality in furniture-making hinge largely on your toolkit.

From the indispensable marking gauge for accurate layout to the finesse provided by a well-honed chisel, the array of tools you need might seem daunting.

Yet, before you brush off the sawdust and walk away, consider how these tools open up a world of creativity and precision in your projects.

Stick around, and let’s explore how the right selection can transform your woodworking from makeshift to masterful.

Contents

Essential Woodworking Tools

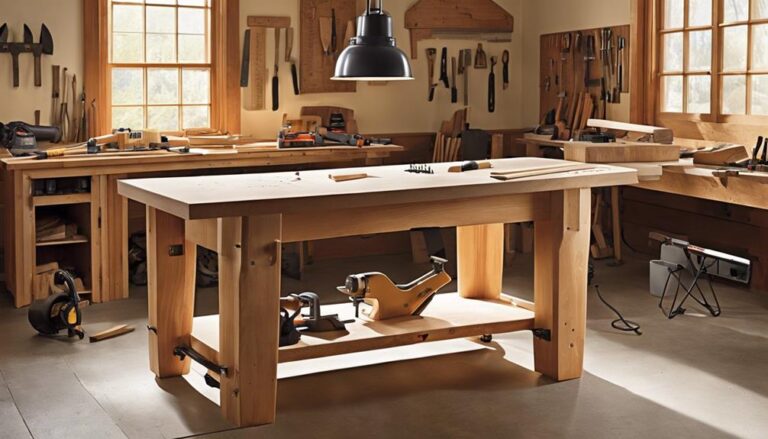

When embarking on the journey of custom furniture making, you’ll find that essential woodworking tools, such as a table saw and router, become your trusted allies in crafting pieces that truly stand out.

Imagine your table saw’s blade slicing through wood with precision, ready for joinery that fits like a glove. Your router, with its array of bits, adds intricate details and curves, transforming the ordinary into the extraordinary.

Chisels and a wooden mallet await to chisel in personality, while clamps hold your vision steady, ensuring every glue-up is flawless. The smoothing plane and card scraper work in tandem, erasing any imperfection, and leaving behind surfaces smooth as silk.

Don’t forget your ruler for precise measurements, safety glasses for protection, and drawer slides for seamless operation. These tools don’t just build furniture; they bring your creative vision to life.

Precision Cutting Equipment

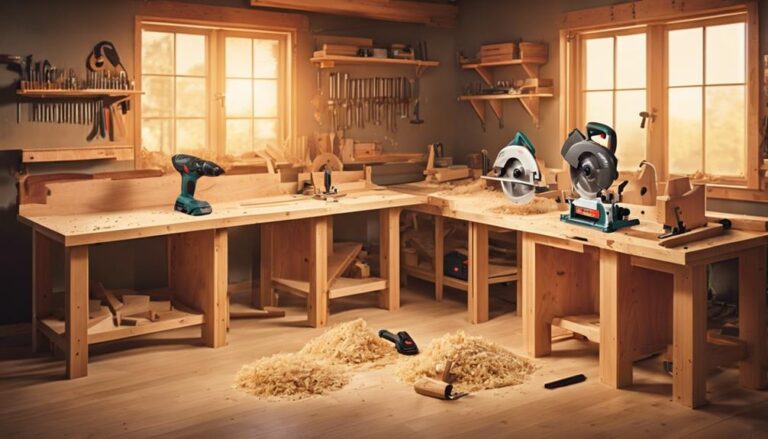

Crafting the perfect piece of custom furniture starts with precision cuts, and for that, a table saw equipped with a high-quality blade becomes your indispensable partner. It’s essential for those precise and straight cuts, but it’s just the beginning.

When you’re breaking down large sheet goods, a track saw ensures your cuts are accurate and splinter-free, crucial for maintaining the integrity of your custom pieces. For angles and crosscuts that need to be spot-on, a miter saw steps up to the plate.

Don’t forget the versatility of a band saw for those intricate curves and designs, adding character to your creations. And for the finishing touches, a jigsaw allows you to cut detailed shapes and curves, making your custom furniture truly one-of-a-kind.

Joinery Instruments

After mastering the precision cuts, it’s crucial to focus on joinery instruments for assembling your custom furniture with strength and elegance. For those eye-catching, hand-cut dovetails, nothing beats the precision of a Dovetail Saw and a Coping Saw. These saws allow you to create clean joints that aren’t only strong but also visually appealing in your custom furniture.

Chisels, in a variety of sizes, become indispensable for cutting and shaping wood, ensuring your joinery work fits seamlessly. A Shoulder Plane then steps in to fine-tune these joints, guaranteeing a perfect fit and smooth finish.

Don’t forget, that accurate layout tools are your best friends, whether you’re working with power tools or doing handwork. These instruments ensure your creations aren’t only durable but also boast unmatched craftsmanship.

Surface Finishing Tools

To elevate your custom furniture to the pinnacle of craftsmanship, mastering the use of surface finishing tools is crucial for that flawless, touchable finish. Here’s a quick guide to ensure your wood surfaces gleam with a professional finish:

- Random Orbit Sander: It’s your go-to for smooth and consistent finishes. Its versatile action reduces swirl marks, prepping your custom furniture for that final touch.

- Card Scraper: This simple hand tool is a game-changer for removing imperfections. It leaves wood surfaces glass-smooth, ready to absorb finishes evenly.

- Smoothing Plane and Block Plane: These tools are essential for creating flat surfaces, crisp chamfers, and leveling joints. They’re the secret to enhancing the aesthetic appeal of your pieces, ensuring each edge and corner contributes to a seamless, professional look.

Clamping and Assembly Gear

In the world of custom furniture making, clamps and assembly gear are the unsung heroes that hold your creations together, ensuring every joint is tight and every line is straight.

| Clamps | Workmates | Puttering Benches |

|---|---|---|

| Bar Clamps | Portable Workbench | Sturdy Framework |

| C-Clamps | Folding Design | Adjustable Height |

| Pipe Clamps | Quick Clamping | Accessory Storage |

| Spring Clamps | Lightweight | Mobility |

| Hand Screw Clamps | Stability | Worktop Versatility |

These are vital for maintaining alignment, preventing movement during glue-ups, and providing the flexibility needed across various woodworking projects. Whether you’re piecing together a delicate chair or a robust dining table, the right clamping gear is crucial for a successful assembly. They apply the necessary pressure for strong, durable joints—truly making or breaking your custom furniture endeavors.

Conclusion

In wrapping up, you’ve got the blueprint for crafting bespoke furniture that not only stands out but endures. From the precision of marking gauges to the finesse of block planes, every tool in your arsenal plays a pivotal role.

Remember, it’s not just about cutting and joining wood, but sculpting pieces that tell a story. So, clamp down, measure twice, cut once, and let those shavings tell tales of craftsmanship.

Here’s to creating not just furniture, but legacies.